In modern electrical and autoation systems, reliability and safety are essential. The PVC Insulated Power Control Cable is designed to provide dependable power distribution and control signal transmission for a wide range of industrial and commercial environments.

Known for its excellent insulation properties, cost-effectiveness, and durability, this cable is an ideal choice for power plants, construction sites, control panels, and building automation systems. Manufactured under strict quality standards, the PVC Insulated Power Control Cable ensures optimal performance and long service life, even under challenging operating conditions.

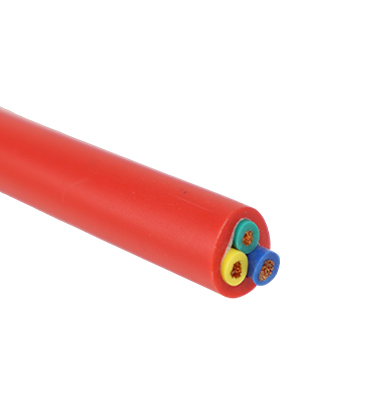

A PVC Insulated Power Control Cable is a multi-core electrical cable designed for low- to medium-voltage applications. It features copper conductors insulated with polyvinyl chloride (PVC), providing protection against heat, moisture, mechanical stress, and chemical exposure.

Conductor: High-purity annealed copper for superior conductivity.

Insulation: Premium-grade PVC for mechanical and thermal stability.

Inner Sheath (optional): Additional protection against friction and oil.

Armoring (optional): Steel wire or tape for enhanced mechanical protection.

Outer Sheath: PVC jacket that resists UV, oil, and weather exposure.

| Feature | Description | Customer Benefit |

|---|---|---|

| High Insulation Resistance | PVC insulation minimizes current leakage and electrical loss | Enhanced safety and energy efficiency |

| Durability | Resistant to abrasion, chemicals, and moisture | Long lifespan, even in harsh conditions |

| Temperature Performance | Operates from -15°C to +70°C | Reliable in diverse climates |

| Flexibility | Easy to bend and route during installation | Reduced labor and setup time |

| Cost Efficiency | Economical material and production | Lower overall project cost |

| Compliance | Meets IEC, BS, and UL standards | Global acceptance and certification |

| Color Coding | Multiple insulation colors available | Simplified identification and maintenance |

These key features make PVC Insulated Power Control Cables a trusted choice for electricians, engineers, and system integrators around the world.

PVC Insulated Power Control Cables are used across multiple industries and installations, including:

Industrial Automation Systems

Connecting sensors, controllers, motors, and actuators.

Power Distribution Panels

Safe and efficient control of voltage and current flow.

Building Wiring and Lighting Systems

Stable connections for commercial and residential power circuits.

Construction and Infrastructure Projects

For control circuits and signaling in high-rise buildings and industrial sites.

Renewable Energy Systems

Used in solar and wind installations for power and monitoring systems.

Marine and Offshore Applications

Suitable for environments with moderate vibration and moisture exposure.

| Parameter | Specification |

|---|---|

| Conductor Material | Annealed bare or tinned copper (Class 5) |

| Insulation Material | PVC Type A or Type B |

| Rated Voltage | 450/750V or 0.6/1kV |

| Conductor Size | 0.5 mm² – 35 mm² |

| Temperature Range | -15°C to +70°C |

| Flame Retardancy | IEC 60332-1 compliant |

| Test Voltage | 2000V / 5 minutes |

| Minimum Bending Radius | 6 × cable diameter |

| Standards | IEC 60227 / BS 6004 / UL 62 |

| Certifications | CE / RoHS / ISO 9001 |

Proper installation ensures optimal cable performance and longevity. Follow these professional guidelines for a safe and efficient setup.

Cable cutter and stripper

Screwdrivers and torque wrench

Crimping tools and terminals

Electrical tape or heat-shrink tubing

Before installation:

Verify cable specifications and length.

Inspect for visible damage or deformation.

Ensure power is fully disconnected before working.

Measure and Cut: Cut the cable to required length, leaving extra for termination.

Strip Insulation: Remove outer sheath and insulation carefully to avoid damaging conductors.

Terminate Conductors: Use proper lugs or connectors for secure electrical contact.

Lay the Cable: Route the cable smoothly without twisting or sharp bends.

Fix and Label: Secure using cable ties or clamps and label both ends clearly.

Testing: Perform continuity and insulation resistance tests before energizing.

Avoid pulling on the cable during installation.

Maintain adequate spacing from heat sources or corrosive materials.

Follow local electrical codes and standards.

Quality assurance is a vital part of our production process. Every PVC Insulated Power Control Cable undergoes comprehensive testing from raw material selection to final delivery.

| Stage | Inspection Method | Purpose |

|---|---|---|

| Raw Material Check | Copper purity, PVC density, tensile test | Ensure material reliability |

| In-Process Testing | Diameter measurement, insulation concentricity | Maintain uniformity during production |

| Electrical Testing | Conductor resistance, voltage withstand test | Verify electrical performance |

| Mechanical Testing | Bending, elongation, and abrasion resistance | Guarantee physical durability |

| Environmental Test | Heat aging, cold flexibility, oil resistance | Assess real-world performance |

| Final Inspection | Marking, packaging, labeling | Confirm export readiness |

Our PVC Insulated Power Control Cables are manufactured under the ISO 9001:2015 Quality Management System and comply with:

IEC 60227 / IEC 60502

BS 6004

UL & CSA Standards

CE, RoHS, and REACH Directives

Customers receive a complete quality inspection report and certificate of conformity with every shipment, ensuring product traceability and confidence.

John M., Electrical Engineer (UK)

“The PVC Insulated Power Control Cables we ordered were delivered on time and met all IEC standards. Installation was smooth, and performance has been excellent in our factory automation systems.”

Maria L., Procurement Manager (Brazil)

“Outstanding quality at a competitive price. We appreciated the detailed test report and fast technical support during installation.”

Liang Wei, Project Supervisor (Singapore)

“Durable and flexible cables that handle bending and heat well. Excellent for power distribution and control panel wiring.”

| Category | Rating (1–5) |

|---|---|

| Product Quality | 4.9 |

| Delivery Time | 4.8 |

| Technical Support | 4.9 |

| Overall Satisfaction | 4.9 |

These positive customer experiences reinforce our reputation as a trusted cable manufacturer and supplier in the global electrical industry.

To ensure long-term cable performance, follow these expert maintenance recommendations:

Check for visible wear, cracks, or discoloration.

Test insulation resistance periodically.

Ensure cable terminations remain tight and corrosion-free.

Use a soft dry cloth; avoid solvents that can damage PVC insulation.

Keep cable surfaces free from dust and oil build-up.

Store in a cool, dry place, away from direct sunlight and heat sources.

Avoid stacking heavy objects on top of coils.

Maintain coils on reels or racks to prevent deformation.

Following these steps helps maintain safety, performance, and compliance throughout the cable’s service life.

We ensure that every shipment arrives safely and on time.

Packaging: Wooden drums, steel reels, or coils with waterproof wrapping.

Labeling: Product code, voltage rating, length, and batch number.

Delivery: Global logistics partners with sea, air, and express options.

Lead Time: Typically 7–15 working days depending on quantity.

Customized packaging and OEM labeling are available for distributors and large-scale projects.

Over 20 years of manufacturing expertise

Certified quality and global compliance

Competitive factory pricing and stable supply

OEM/ODM customization options

Responsive technical and after-sales support

We serve industries worldwide with high-quality, tested, and certified cables that deliver reliability and performance at every connection point.

The PVC Insulated Power Control Cable is a cost-effective and durable solution for power transmission and control in both industrial and commercial environments. With excellent insulation properties, mechanical strength, and easy installation, it meets the needs of modern engineering and electrical design.

Supported by strict quality inspection, positive customer feedback, and professional technical service, this cable represents the ideal combination of performance, safety, and value.

Choose our PVC Insulated Power Control Cable to power your projects with confidence, consistency, and quality you can trust.

本网站使用 cookie 来确保您在我们的网站上获得最佳体验。